Acceptance Sampling is one of the oldest quality tools, however is commonly misunderstood and frequently misused. This training will help you rise the effectiveness and consequently lower your product disposition cost. It also teaches you how to select and evaluate acceptance sampling plans for different uses. Such sampling plans can be used for incoming inspection, in-process components and finish goods.

WHO SHOULD ATTEND

Upper Management, Managers, Supervisors, Engineers, Team Leaders and individuals interested in learning Acceptance Sampling.

BENEFITS

When this training is completed, you will be able to evaluate, design and implement sampling plans for attributes and variables that will improve your outgoing quality and the overall cost.

TRAINING TOPICS:

I. Introduction

- Definition of Accepting Sampling

- Purpose of Acceptance Sampling

- Alternatives to Acceptance Sampling

- Variety of Situations

II. Evaluating Single Sampling Plans

- Characterizing Single Sampling Plans

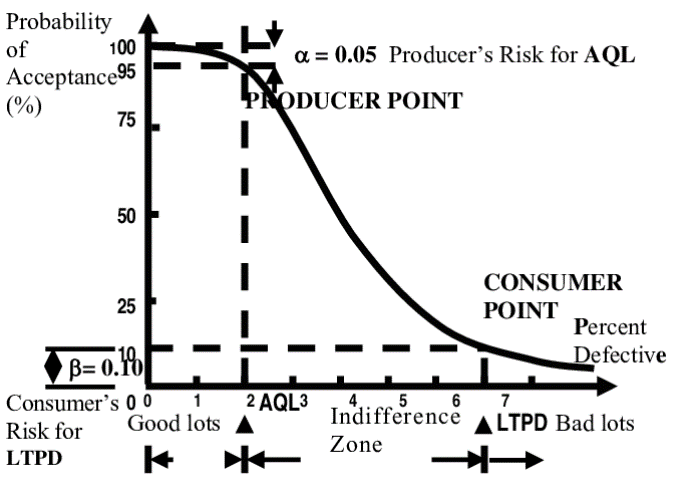

- Probability of acceptance

- OC Curves

- Summarizing OC Curves

- AOQ Curves and AOQL

- ASN Curves

III. Selecting Single Sampling Plans

- Selecting Plans Based on AQL and LTPD

- Selecting Plans Based on AQL and AOQL

- Selecting Plan to Reject the Obvious

IV. Economical Single Sampling Plans

- Definition of Accepting Sampling

- Purpose of Acceptance Sampling

- Alternatives to Acceptance Sampling

- Variety of Situations

V. Practical Considerations

- Why Acceptance Sample?

- Comparison of Methos for Selecting Plans

- Process Monitoring

- 100% Inspections

- Defect Categories

- Where to Place Inspections

- Forming Lots

- Selecting Samples

- Sample Sizes for Special Studies

- Effect of Inspection Errors

- Incentive for Improvement

- Zero Acceptance Number Sampling Plans

VI. Double Sampling Plans

- Characterizing Double Sampling Plans

- OC Curves

- AQL, IQ, LTPD and AOQL

- AOQ Curves

- ASN Curves

- Selecting Plans Based on AQL and LTPD

- Selecting Matching Double Sampling Plans

- Reinspection

- Multiple and Sequential Sampling Plans

VII. Quick Switching Systems

- Characterizing Quick Switching Systems

- Stationary and Transitive OC Curves

- Summarizing Protection

- AOQ Curves

- ASN Curves

- Selecting QSSs Based on AQL and LTPD

- Using QSSs to Improve Protection

- Monitoring Processes

- Comparison to Chain Sampling Plans

VIII. Mil-Std-105E, ANSI/ASQC Z1.4 - 2003

- The ANSI/ASQ Z.4 Indexing System

- Matching Double Sampling Plans and QSSs

- ANSI/ASQ Z1.4 Switching rules

IX. Variable Sampling Plans

- The Normal Distribution

- Characterizing Variable Sampling Plans

- Evaluating Variable Sampling Plans

- Selecting Variable Sampling Plans

- Known Standard Deviation

- Attributes Versus Variables Sampling Plans

- Normality Assumption

- Variables Inspection for Parameters

- Measurement Error

- Mil Std 414, ANSI/ASQC Z1.9 - 2003

- Selecting the Type of Sampling Plan