MSA (Measurement System Analysis) analyses the collection of equipment, operations, procedures, software and personnel that affects the assignment of a number of measurement characteristics. MSA considers the following: Selection of the correct measurement and approach, assess the measuring device, assess procedures and operators, calculate the measurement uncertainty including calibration studies, fixed effect ANOVA, components of variance, attribute gage study, gage R&R, ANOVA gage R&R and destructive testing analysis.

WHO SHOULD ATTEND

Managers, Supervisors, Engineers, and manufacturing and quality Team Leaders from all functional areas.

BENEFITS

We determine type of study target and acceptance criteria, percent of tolerance and/or capability of Gauge for the Analyses the collection of equipment, operations, procedures, software and personnel that affects the assignment of a number of measurement characteristics.

TRAINING TOPICS:

Introduction

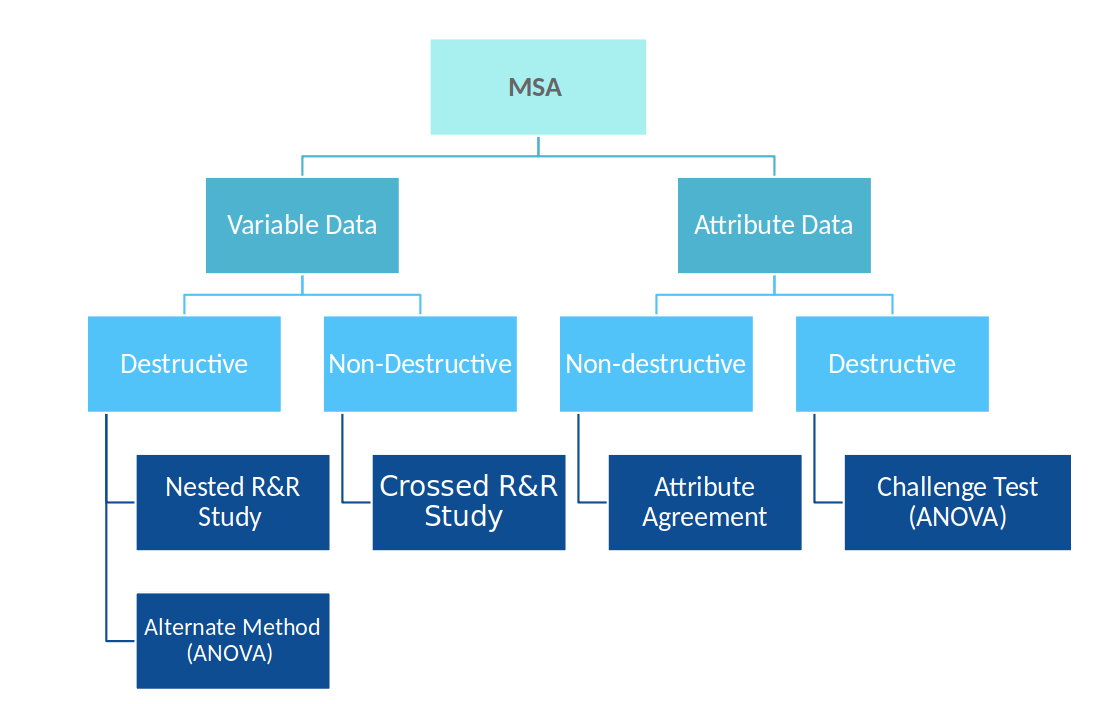

- MSA: Identify and quantify the amount of variation in the process that can be attributed to the measurement system

- Repeatability: The variation in measurements obtained when one measurement device is used several times by the same person to measure the same characteristic on the same product

- Reproducibility: The variation in measurements made by different people using the same measuring device to measure the same characteristic on the same product

- Measurement Instrument

Variable Data Testing

- Destructive

- Nested R&R

- Alternate method ANOVA

- Non-Destructive

- Cross R&R Study

Attribute Data Testing

- Destructive

- Challenge Test ANOVA

- Non-Destructive

- A tribute agreement