This training will take you from the traditional sampling plans to perform incoming inspection to the RM supplier process monitoring through EWMA statistical charts. We’ll show you step-by-step how to develop your RM suppliers and implement the raw material supplier parts certification and how to monitors the RM Supplier Quality using the Supplier Quality software.

WHO SHOULD ATTEND

Upper Management, Managers, Supervisors, Engineers, and Team Leaders from the Quality, Purchasing and Planning functional areas.

BENEFITS

When the training is completed, you will be able to use the software as a linkage between the RM Suppliers and your company, which will bring significant benefits for both your RM Suppliers and your Organization. This new partnership will result in a win-win situation. Eliminate/Reduce incoming inspection by consistently ensuring compliance with specifications through EWMA control charts. This process will result in a significant reduction of shipments rejection. Lower the transportation cost by eliminating the need for incoming inspection and therefore allowing for raw material suppliers to ship the product directly to the manufacturing final destination. This process has been well accepted by FDA and ISO notified bodies.

TRAINING TOPICS:

Introduction

- Raise the Level of Partnership with Raw Material Suppliers

- Implement Prevention at the Source

- Continues interaction/follow up

- Stop/Reduce Incoming Inspection

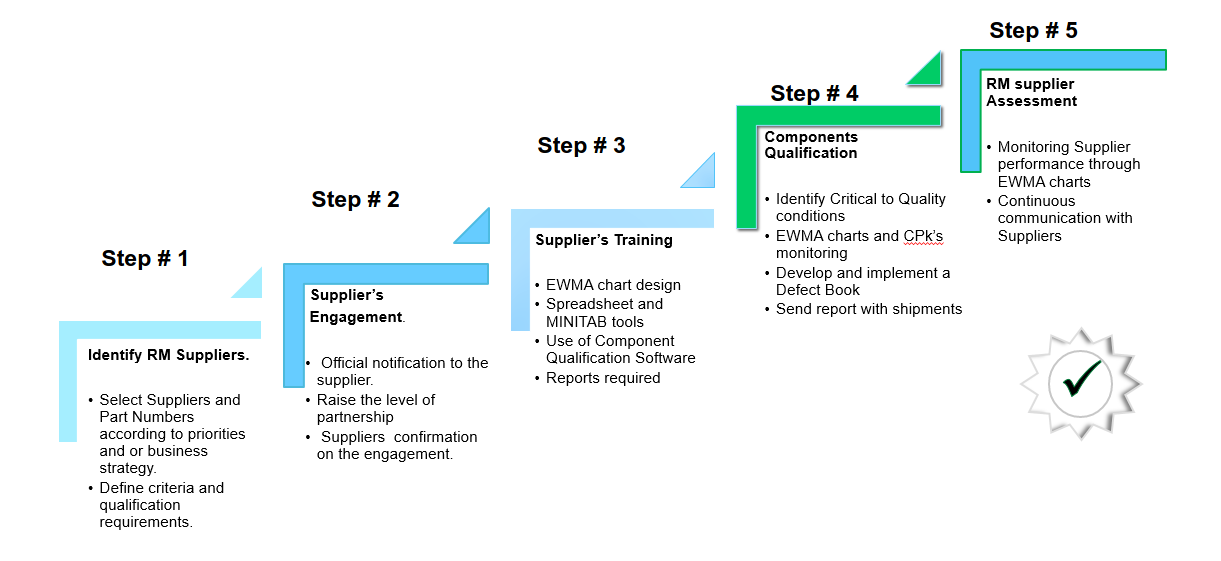

Component Qualification Process

- Identify RM Suppliers.

- Select Suppliers and Part Numbers according to priorities and or business strategy

- Define criteria and qualification requirements

- Supplier’s Engagement

- Official notification to the supplier

- Raise the level of partnership

- Suppliers’ confirmation on the engagement

- Supplier’s Training

- EWMA chart design

- Spreadsheet and MINITAB tools

- Use of Component Qualification Software

- Reports required

- Components Qualification

- Identify Critical to Quality conditions

- EWMA charts and CPk’s monitoring

- Develop and implement a Defect Book

- Send report with shipments

- RM supplier Assessment

- Monitoring Supplier performance through EWMA charts

- Continuous communication with Suppliers